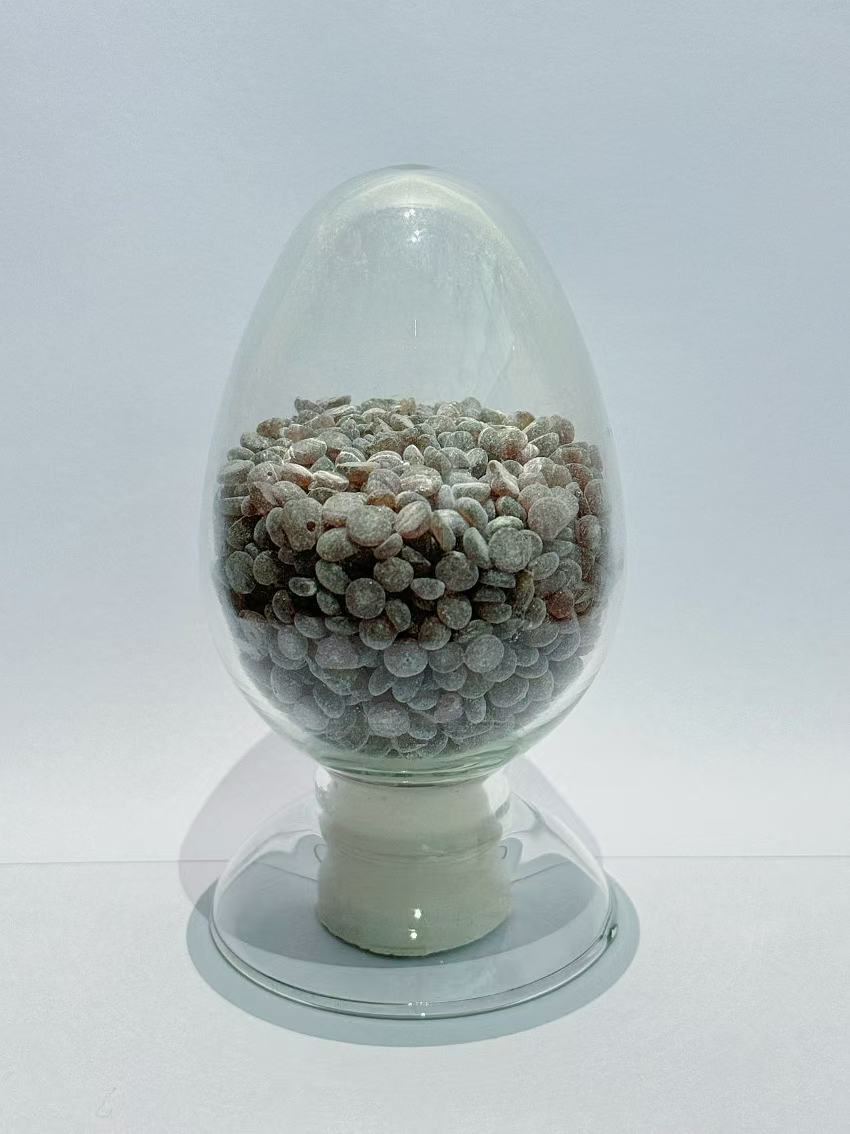

In the world of adhesives, the quest for improved adhesive durability is never-ending. One of the key players in this realm is the tackifying resin, a component that significantly enhances the adhesive strength of materials. Tackifying resins are essential in bonding rubber to various substrates, providing a robust and long-lasting connection. They are particularly effective in industrial applications where strong adhesion is critical. The Rubber Tackifier STK is a prime example of such a resin, specifically designed to have excellent initial adhensiveness, storage adhensiveness and heat-humidity adhensiveness. By understanding the role of tackifying resins, industries can unlock new levels of performance and reliability in their adhesive solutions.

Table of contents:

How Tackifying Resin Transforms Adhesive Performance: A Step-by-Step Guide

Common Myths About Tackifying Resin You Need to Stop Believing

The Future of Adhesive Durability: Trends in Tackifying Resin Technology

Tackifying Resin in Action: Real-World Applications and Success Stories

How Tackifying Resin Transforms Adhesive Performance: A Step-by-Step Guide

Tackifying resins work by altering the physical properties of adhesives, making them more flexible and sticky. This transformation begins with the integration of resins into the adhesive formulation. The resin modifies the adhesive’s molecular structure, increasing its ability to wet surfaces and form strong bonds. The Rubber Tackifier STK, for instance, is known for enhancing the adhesive durability of rubber materials when applied to various substrates. This process involves a delicate balance of temperature, pressure, and time to ensure optimal performance. As a result, the adhesive becomes more adaptable to different environmental conditions, maintaining its strength and integrity over time. By following this step-by-step approach, industries can achieve superior adhesive performance that meets their specific needs.

Common Myths About Tackifying Resin You Need to Stop Believing

Despite their proven benefits, several myths about tackifying resins persist. One common misconception is that all resins perform the same function. In reality, each type of resin is engineered for specific applications and substrates. Another myth is the belief that resins compromise the environmental sustainability of adhesives. However, many modern resins, including those used in the Rubber Tackifier STK, are designed with eco-friendly components. Additionally, some believe that resins are a one-size-fits-all solution, but the truth is that they must be carefully selected and formulated to match the adhesive’s intended use. By dispelling these myths, industries can make informed decisions and fully leverage the benefits of tackifying resins.

The Future of Adhesive Durability: Trends in Tackifying Resin Technology

As technology advances, so does the field of tackifying resins. One of the most promising trends is the development of resins that enhance adhesive durability without compromising environmental standards. Innovations in resin formulation are leading to products that are both effective and sustainable. The incorporation of advanced materials is paving the way for resins with superior bonding capabilities. These trends indicate a bright future for tackifying resins, with continued improvements in both functionality and environmental responsibility.

Tackifying Resin in Action: Real-World Applications and Success Stories

Tackifying resins have a wide range of applications across various industries. In the automotive sector, they are used to bond rubber components to metal frames, ensuring long-lasting durability. The construction industry relies on these resins for creating strong, weather-resistant seals in building materials. One success story involves a company that used the Rubber Tackifier STK to improve the adhesion of rubber gaskets in heavy machinery, resulting in reduced maintenance costs and increased equipment lifespan. These real-world applications demonstrate the versatility and effectiveness of tackifying resins in enhancing adhesive durability.

In summary, tackifying resins play a crucial role in improving the performance and reliability of adhesives. By understanding their properties and dispelling common myths, industries can make informed decisions about their adhesive solutions. With advancements in resin technology developing, the future of adhesive durability looks promising. The Rubber Tackifier STK exemplifies the potential of these resins to transform adhesive performance, providing robust and long-lasting bonds in various applications. As industries continue to explore and innovate, tackifying resins will remain a key component in the quest for stronger, more durable adhesives.